Video

Seamless medium carbon steel boiler and superheater tubes

Product Manufacturing Process

Tube blank

Inspection (spectral detection, surface inspection, and dimensional inspection)

Sawing

Perforation

Thermal inspection

Pickling

Grinding inspection

Lubrication

Cold drawing

Lubrication

Cold-drawing (the addition of cycled processes such as heat treatment, pickling and cold drawing should be subject to the specific specifications)

Normalization

Performance test (mechanical property, hardness, flattening, flaring, and flanging)

Straightening

Tube cutting

Non-destructive testing (eddy current or ultrasonic)

Hydrostatic test

Product inspection

Packaging

Warehousing

Product Manufacturing Equipment

Shearing machine, sawing machine, walking beam furnace, perforator, high-precision cold-drawing machine, heat-treated furnace, and straightening machine

Product Testing Equipment

Product Applications

Seamless Tubing Manufacturing

Knowing that distinction can also help in determining which tubing is best for a given application, welded or seamless. The method of manufacturing welded and seamless tubing is evident in their names alone. Seamless tubes are as defined – they do not have a welded seam. The tubing is manufactured through an extrusion process where the tube is drawn from a solid stainless steel billet and extruded into a hollow form. The billets are first heated and then formed into oblong circular molds that are hollowed in a piercing mill. While hot, the molds are drawn through a mandrel rod and elongated. The mandrel milling process increases the molds length by twenty times to form a seamless tube shape. Tubing is further shaped through pilgering, a cold rolling process, or cold drawing.

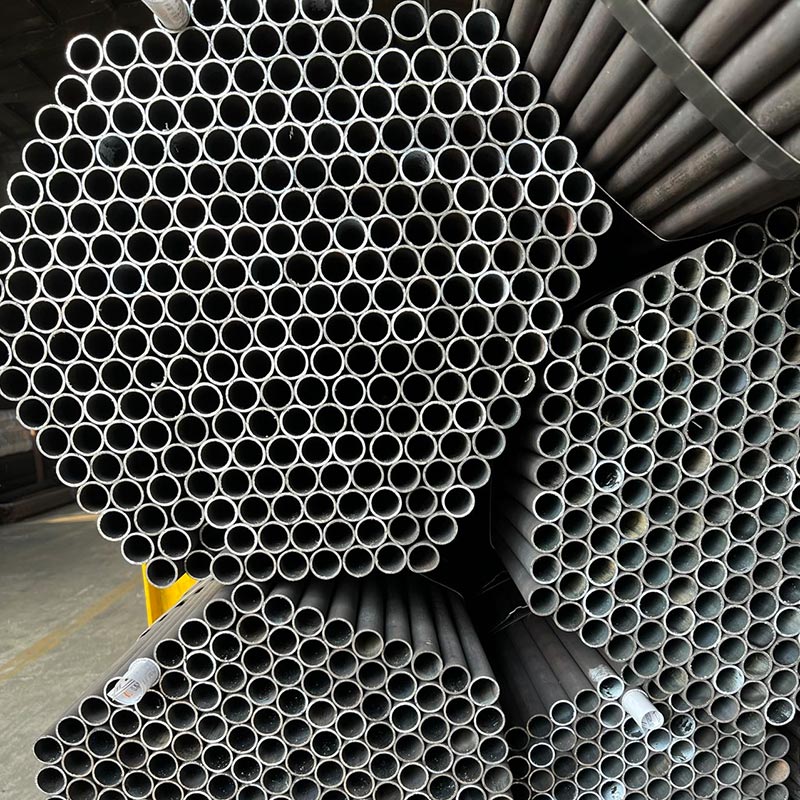

Package of carbon steel seamless pipe

Plastic caps plugged at the two sides of pipe ends

Should be avoided by the steel strapping and transport damage

Bundled sians should be uniform and consistent

The same bundle(batch) of steel pipe should be came from the same furnace

The steel pipe has the same furnace number,the same steel gradethe same specification